Takt time is the rate of customer demand for the group, or family, of products produced by one process. Takt time is used most often at assembly-type processes that serve external customers.

Takt time is calculated by dividing the effective operating time of a process (for example, per shift or day) by the quantity of items customers require from the process in that time period (Figures 5-2 and 5-3). “Effective operating time” is the available time minus planned downtimes such as lunches, breaks, team meetings, cleanup, and planned maintenance. Note that unplanned downtimes and changeover times are not subtracted at this point, because they are variables you want to reduce.

Say an assembly process has 26,100 seconds effective operating time per shift, and over some period of time the customer requires an average of 450 pieces per shift:

The quotient of 58 seconds means that, based on our available time, on average the customer is currently buying one unit every 58 seconds.

takt time = your effective operating time per shift / quantity customer requires per shift

Figure 5-2. The takt time calculation

26,100 seconds available time / 450 pleces required = 58 seconds takt time

Figure 5-3. Calculating takt time

How is this number used?

It does not automatically mean you should produce at a rate of one piece every 58 seconds. The actual intended cycle time of an assembly process, called planned cycle time, is usually less (faster) than the takt time. For example, if there is a changeover time between different part types, we have to cycle the process faster than takt in order to compensate for time lost during changeovers. So in a sense takt time represents an ideal repetitive cycle for an assembly process, a cycle at which we would be producing in sync with the customer demand rate—sell one, make one.

The Intention Behind Takt Time

Takt time becomes interesting in our discussion of target conditions when we use it as something to strive for. Two ways to do this are trying to produce consistently to planned cycle time, and trying to move the planned cycle time closer to the takt time.

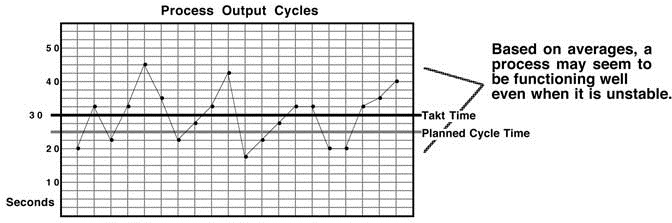

Trying to produce consistently to planned cycle time means striving to develop a stable process. Many of us track pieces produced per hour or per shift and therefore are unable to answer the question: “At how many seconds per piece should this process be cycling?” We have an aggregate outcome target, but not a target condition, and we get trapped by such outcome metrics because they prevent us from seeing the actual condition of the process. The result is that an astonishing number of processes come close to making their numbers on average, but their output cycles actually fluctuate well out of statistical control from cycle to cycle (Figure 5-4). This condition is not only expensive (requiring extra resources) and adversely affects quality, but many process improvement efforts will simply not stick when the process is out of control.

Figure 5-4. An unstable process

When you have identified the degree of fluctuation from cycle to cycle in a process, the next question becomes: “What should the range of fluctuation be?” With that desired condition in mind, you can then observe the process with an eye to identifying, understanding, and eliminating obstacles to that condition.

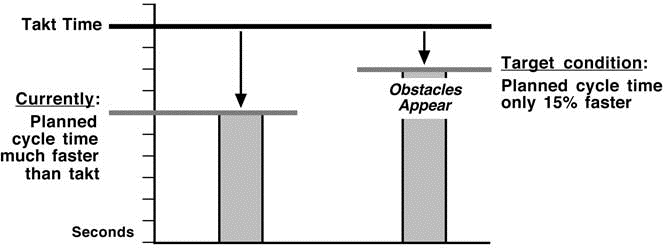

Once a process cycles relatively consistently, you have a basis to possibly go further by striving to reduce the gap between takt time and planned cycle time. For example, we might establish a process target condition that includes a planned cycle only 15 percent less (faster) than takt time. As you try to achieve this condition you will again discover obstacles (changeovers, machine downtime, scrap, absenteeism, etc.) you need to work on (Figure 5-5).

Takt time and planned cycle time are only one part of a target condition for a production process, and I am not suggesting that utilizing takt time in this way is the priority improvement for every situation. The point is, we have missed the target-condition intention behind it. Most factories I have visited know about takt time and even calculate it, but so far I’ve found few factories outside of the Toyota group that use takt time as something to strive for in the manner described here. Only then does it become useful.

Figure 5-5. Reducing the gap between takt time and planned cycle time

Note: Toyota subtracts changeover time in calculating the planned cycle time of a process, but not unplanned downtime, which is made up with overtime, as necessary, at the end of each shift, rather than by further speeding up the planned cycle time to compensate for it in advance. This is done to keep problems visible. Of course, to take this approach you need a time gap between shifts that can accommodate such overtime.

I once mentioned to one of Toyota’s supplier support specialists that I’d figured out how to see what one needs to work on at a process. My idea was to ask the supervisor what would happen if we were to slow his process cycle down so it was only 15 percent faster than the customer takt time. The obstacles and objections that the supervi- sor mentioned would be what we needed to work on!

“Well,” the specialist replied, “the supervisor will be telling you her opinion. To understand the true obstacles, maybe you should build up a little safety stock and temporarily run the process at the slower cycle time. The obstacles that then actually arise are the true ones you need to work on next.”