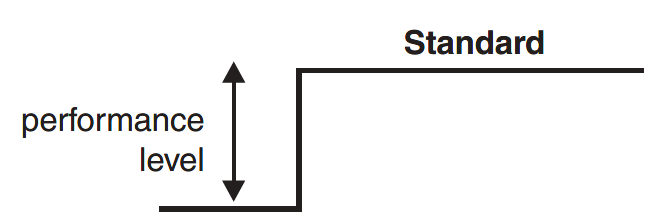

Over time and with practice you should be able to develop a kind of target condition thinking, and Toyota’s concept of “standardized work” helps illustrate what I mean. A “standard” is a description of how a process should operate. It is the prespecified, intended, normal pattern (Figure 5-25).

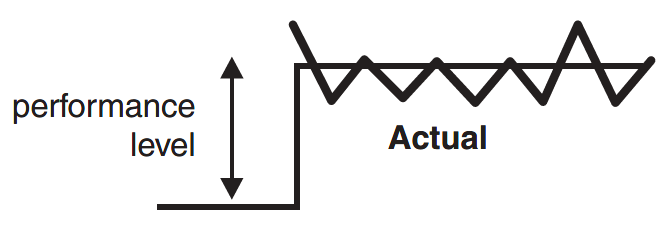

On the other hand, at Toyota “standardized work” means, in essence, that a process is actually operating as specified by the standard (Figure 5-26). Standardized work is a condition, and you can look at a process and ask, “Does that condition exist or not?”

Figure 5-25. A “standard” = how a process should operate

Figure 5-26. “Standardized work” = the process is actually operating as the standard specifies

At a manufacturing conference in Chicago a group of Toyota’s production system specialists presented how they improved a production process at a supplier’s facility. During the presentation someone in the audience asked the speakers, “Do you post standards in the production line?” In typical Toyota fashion (the student should learn for himself ), the answer was brief, “Yes, we do.” I noticed a lot of audience members writing this down, and envisioned them posting standards over the heads of their operators in the false assumption that this would improve something. So I asked a follow-up question: “Who are the work standards for?”

“Well,” came the reply, “when it was time to post the standards in the line”—Toyota does not always post them in the line—“we had to decide whether to post them facing the operators or facing the aisle.” The speaker paused for effect and said, “We posted them facing the aisle.”

The aisle side is where the team leader is, and it is the team leader who primarily uses the work standard.

The key question is not, “Have we posted work standards?” but rather, “How do we achieve standardized work?” The primary intention of specifying standards at Toyota is not, by doing so, to establish discipline, accountability, or control the workers, but rather to have a reference point; to make plan-versus-actual comparison possible, in this case by the team leader, so that gaps between what is expected and what is actually occurring become apparent. In this way we can see what the true problems are and where improvement is needed.

When we are asked if we have standardized work, we usually point to a posted work standard as evidence and say, “Yes, see, we have standardized work.” When a Toyota person is asked the same question, they also look for the standard, but then observe the process and compare it to the standard. If there is a difference between the two—and there often is, even at Toyota—they say, “Not yet.” Toyota is achieving quality excellence, for example, not because a process is done the same way each time, but because Toyota is striving to achieve the target condition of the process being done the same way each time. The difference is subtle, but it’s important if you want to understand and successfully emulate Toyota’s success.

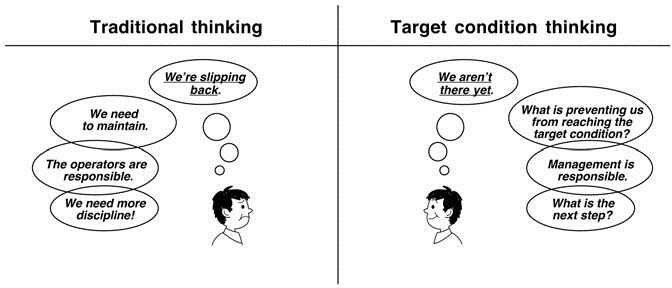

Figure 5-27. How do we think when an abnormality occurs?

How we are thinking about standards is also revealed when there is an abnormality in a process (Figure 5-27). In the traditional way of looking at it, we think the abnormality means we are slipping back; that we need a corrective action and more discipline. My impression is that the Toyota way of thinking turns this around: the abnormality means we have not yet reached the target condition, and we need to keep applying the improvement kata.

So what is the difference between a standard and a target condition? In many cases not much. A good way to think of many standards is as something you are striving to achieve, and the main issue is: “How we will get this processes to actually operate as described in the standard?” That is the hard work. (More on that in Chapter 6.)

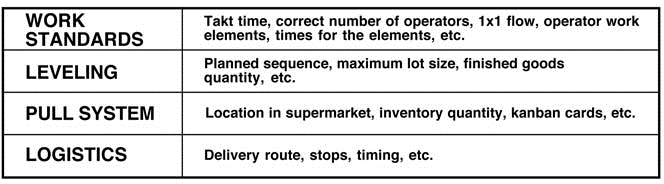

So the following standards, and many others in a factory, can be seen as target conditions (Figure 5-28).

Consider what could be achieved if everyone in your company learned to think of such standards not as straitjackets, but as target conditions to strive for.

Figure 5-28. These standards, and many others, can be viewed as target conditions